Our History

We began in 1876 in Chicago when Nels Johnson founded the N.M. Johnson Company, “Blank Book Manufacturers and Book Binders”. The company’s first advertisement appeared in the 1876-77 Chicago Business Directory – calling “the attention of Merchants, Bankers and Business Men generally, to our Superior Facilities for the manufacture of Blank Books”. In 1896 Thomas Stephen Quin joined the company and the business was renamed Johnson & Quin.

Throughout the years, J&Q has prospered by deploying the latest technologies and adapting to the changing marketplace. We led the introduction of laser printing to the Midwest in 1979, which soon transformed J&Q into a full-service direct mail production company.

In 2014 the latest technology in printing, a high-speed color inkjet printing system, was installed at J&Q. Color inkjet combines and prints all color images, copy and personalized variables in one production process. Benefits include reduced postage and production costs, unlimited versioning, elimination of preprinted forms and shorter schedules.

We offer the latest in direct mail production, as well as data services, personalization technologies, quality processes and certified data security practices. The innovation, flexibility, and solid financial credentials that propelled us throughout our history remain at the core of the way we work today.

Johnson & Quin’s history includes these highlights:

- 1876 – Nels Johnson opened the N.M. Johnson Company in Chicago. The sign in the window advertised: “Blank Book Manufacturers – Printers & Paper Rulers”.

- 1896 – Thomas Stephen Quin joined Nels Johnson and the company name changes to Johnson & Quin. The company supplied bound, ruled ledger books to banks, accountants, hotels and businesses in downtown Chicago.

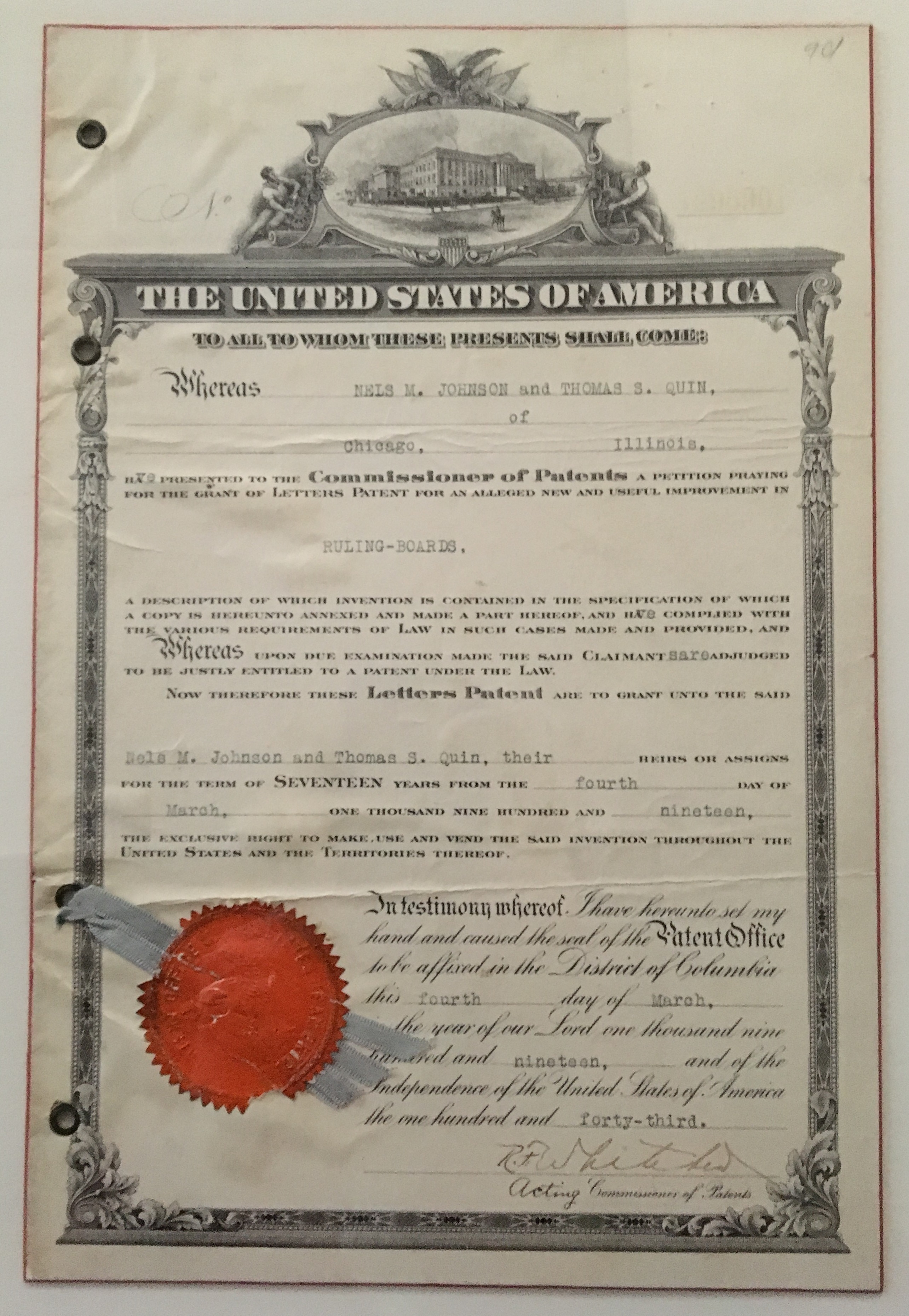

- 1919 – Johnson & Quin looks to the future with its first patent for an improved “Ruling Board”. This tool was used in laying out ruled proofs, making them more accurate.

- 1920s – The Master Printers Federation (now Printing Industry of IL/IN Association) was founded in Chicago. Tom Quin, was chosen as its first president.

- 1928 – Nels’ son, Ralph L. Johnson, joined the company after graduating from Carnegie Tech. Ralph developed the electrocardiograph mounting card that became a standard medical supply for the next 60 years.

- 1930s – The company began to offer large volume commercial printing through modernization and changed to offset printing which replaced letterpress equipment.

- 1933 – J&Q participated with other local businesses and Chicago city officials in planning and staging the Century Progress Exhibition, which injected new growth into the Chicago business community.

- 1960 – Robert I. Henkel joined the J&Q management team. He was instrumental in adding new capabilities in offset printing, and he brought a renewed focus on niche markets, especially the telecommunications industry.

- 1977 – David R. Henkel joined his father at J&Q in a sales and marketing capacity. He was initially assigned the task of developing capabilities within the specialty printing categories.

- 1978 – The Xerox 9700 cut sheet laser printer was introduced at J&Q, the first “print for profit” laser company in the Midwest. J&Q developed successful techniques to assure that preprinted forms ran efficiently in the expensive laser printers.

- 1989 – JQ Technologies, a research and development group, was established. They devised MultiMatch™ technology for assembling multiple personalized pieces into a matched set for mailing, as well as other devices to audit personalized document production.

- 1996 – J&Q acquired selected assets of Graphic Direct, the direct mail printing subsidiary of Graphic Industries. This acquisition broadened the company’s service offerings for true “one stop shopping” in personalized mail production.

- 1999 – In January, new IBM laser printers were purchased to expand J&Q’s work capacity. These printers included an inherent MICR capability that allowed better print quality for MICR check personalization.

- 2000 – J&Q purchased the laser printing assets of MGI, expanding its ability to produce critical documents.

- 2001 – Personalized email was added to J&Q’s array of capabilities, allowing clients to coordinate print and electronic direct campaigns.

- 2006 – David Henkel’s son, Andrew Henkel, joined the company in a sales role and was responsible for selling direct mail and integrated marketing services. He has since become President of J&Q.

- 2008 – J&Q achieved the Forest Stewardship Council (FSC) certification which recognizes the company’s ability to meet environmental responsibility standards. Clients can select from a range of FSC-certified papers for their direct mail.

- 2009 – In July, J&Q acquired certain direct mail production assets, including customer relationships, of InteliMail, a division of Staples Print Solutions in Lenexa, KS.

- 2009 – In December, J&Q was one of the first companies in the Midwest to receive approval by the U.S. Postal Service for the full-service Intelligent Mail® barcode. The IMb offered clients greater control of their mailings, along with reduced postage costs.

- 2010 – J&Q purchased Compuletter, based in Skokie IL, a company that specialized in personalized direct marketing for small to medium-sized companies, fulfillment, database and list management services.

- 2012 – J&Q acquired American Mailers, based in Naperville IL, a division of ANET Corporation. The acquisition considerably expanded J&Q’s high volume capacity.

- 2014 – In December, a Screen Truepress Jet520ZZ high-speed color inkjet printing system was installed which combines the traditional offset printing and personalization steps into a single process. Key benefits include postage savings, shortened turnaround times and unlimited versioning to create highly targeted and effective communications.

- 2015 – In September, the Print+Messenger Color Inkjet System was added to variably print envelopes in color as letters are being inserted. Envelopes can be customized to each person with color images and text to streamline matched mailings and improve response.

- 2016 – In light of the changing security landscape, a new security program was created and went into effect in April resulting in an extremely secure computing environment.

- 2017 – To increase production speed and capabilities, additional high-speed inserters and read/print inkjet systems were added to the lettershop.

- 2018 – Due to high demand for color inkjet production, J&Q added a Screen Truepress Jet520 NX high-speed color inkjet printing system in April. This was Screen’s first color inkjet installation in the U.S. capable of MICR check printing. In September J&Q achieved the AICPA Soc2 security attestation. An independent CPA firm validated J&Q’s security controls to safeguard sensitive client data.

- 2019 – The last monochrome (black only) laser printers left the building in August, 41 years after adding the first laser printer in 1978. All direct mail is now produced on color digital printers. J&Q added a third high-speed color inkjet press, as well as color inkjet envelope printers, high-speed inserters, and high-speed folder/card affixers that match embossed cards to forms.

- 2020 – In March the coronavirus Covid-19 hit the world and 2020 will be written in the history books as the year of another pandemic. We focused on sanitization and health safety for our staff, supporting the plant employees as essential workers to keep producing mail and working remote for most of the office teams.

- 2021 – While people continued to work from home and the new normal was wearing masks and social distancing, direct mail brought in high response rates and our clients mailed in higher volumes. Schedules lengthened as paper was difficult to get and print vendors were inundated with orders and limited by paper allocations.

- 2022 – In response to the additional volumes our clients were mailing, additional high speed inserters and bindery lines were added, as well as a fourth Screen Color Inkjet press. Paper and printed components especially envelopes were difficult to obtain and required longer lead times. We worked closely with our suppliers and came up with creative solutions to keep the mail going out the door on time.

- 2023 – As materials became more readily available, J&Q continued to increase the number of mail pieces produced per year. Additional equipment, such as another MBO high-speed plow folder, was purchased to keep up with these demands.

Patent from 1919 Ruling boards